View the PDF here

New Understanding of Fire Spread on the EPS ETICS Façade

Biao Zhou, School of Emergency Management and Safety Engineering, China University of Mining & Technology (Beijing), Beijing, China;

Hideki Yoshioka, Department of Fire Engineering, Building Research Institute, Ibaraki, Japan;

Takafumi Noguchi, Department of Architecture, Faculty of Engineering, The University of Tokyo, Tokyo, Japan;

Kai Wang, School of Emergency Management and Safety Engineering, China University of Mining & Technology (Beijing), Beijing, China;

Xinyan Huang, Department of Building Services Engineering, The Hong Kong Polytechnic University, Hong Kong, China;

INTRODUCTION

Recent large fires associated with façade systems in tall buildings are currently occurring at a rate of more than once a month globally and are responsible for many deaths and billions of dollars in losses. The 2017 Grenfell Tower façade fire resulted in more than 70 fatalities [1]. In China, many façade fires have happened in almost every large cities, such as the 2009 TVCC fire and the 2010 Shanghai fire.

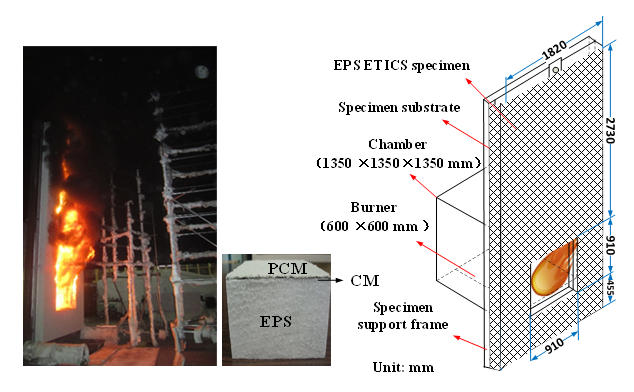

Fig. 1. Typical EPS façade fire: the 2009 TVCC fire in Beijing (left) and the 2010 Shanghai fire (right).

Over the last few decades, External Thermal Insulation Composite Systems (ETICS) have been widely used in buildings due to their thermal advantages, low cost, and ease of application [2]. A typical ETICS is consisted of the wall construction, insulation material, cement bound mortar with reinforcement, and rendering and is fixed by dowels and mortar [3,4]. The flammable insulation materials, like expanded polystyrene (EPS) and polyurethane (PU) foams, are often used. It is well known that EPS ETICS is quite flammable [5]. For the aged EPS ETICS façade, the flame retardancy of polymer cement mortar (PCM) becomes weaker because the outer PCM layer is gradually deteriorated by the environment. Thus, the fire risk of EPS ETICS is very high for the aged facade. A complex fire behavior, including EPS melt-flow and dripping has been reported when EPS ETICS specimens exposed to a fire. The fire spread rate (FSR) of EPS ETICS has been observed to be fast, but the data of FSR on building façade are still lacked today.

The EPS ETICS fire has been one of the hot and challenging topics in building facade fire. Nevertheless, the high cost of large-scale fire tests and the strong influence of scale effect have limited the deeper understanding of EPS ETICS fire research. More fundamental knowledge of vertical upward fire spread rate of EPS ETICS masonry façade fire over the exterior building wall is urgently needed.

FIRE SPREAD TEST OVER FULL-SCALE EPS ETICS

We have conducted a series of real-scale EPS ETICS façade specimens are tested under various HRR of window spilled flame, EPS thickness, and thermal parameters of ETICS according to the JIS A1310 method [6]. The test setup and EPS ETICS specimens are illustrated in Fig. 2. Similar to the previous work [7,8], the facade fire test facility consisted of a propane gas combustion chamber (size in L × W × H = 1,350 mm × 1,350 mm × 1,350 mm), window opening (size in L × W= 910 mm × 910 mm), gas burner (size in L × W= 600 mm × 600 mm), specimen substrate and specimen support frame. The opening size and opening aspect n (n = 2W/H) were W × H = 910 mm × 910 mm and n=2, respectively. The chamber had an inner surface area of 10.1 m2.

Fig. 2. The description of the experiment: the layout of test configurations, EPS ETICS sample and a sketch model of experiment layout [2].

FIRE BEHAVIOR ON EPS ETICS

Fig. 3 illustrates the development of the compartment fire, the ignition of the façade, and the upward spread of the façade fire, based on test No. 4 (1,100 kW fire with 200-mm thick EPS). With the development of the compartment fire (Fig. 3a), the flame spilled out through the window opening and attached to the ETICS surface wall (Fig. 3b). When the hot flame got in contact with on façade surface, the PCM layer would be ignited soon, because of the combustible nature of styrene‐butadiene rubbers‐latex (SBR). Soon after, the CM layer became damaged by window spilled flames (Fig. 3c). Then, flames came into the EPS layer to ignite a new fire, which started to spread both upward and downward (Fig. 3d). The upward fire spread was dominant and much faster. The downward fire spread was accompanied by the dripping ignition of molten EPS. Finally, most of the fuels were burnt out, so the fire became weak. After about 20 min, the flame disappeared, and a big hole was found above the opening (Fig. 3e). No remaining EPS was found when the residual surface was removed (Fig. 3f).

Fig. 3. The description of façade fire tests, (a) Early stage at t = 1 s, (b) flame spilled out at t = 24 s, (c) ignition of EPS and the formation of hole in CM layer at t = 95 s, (d) upward flame propagation at t = 326 s, (e) EPS burnout outlook, and (f) removal of façade [2,9].

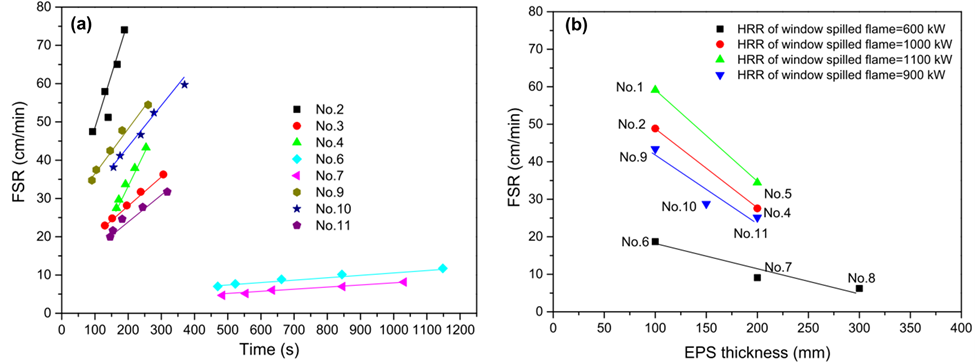

Once the EPS foam is directly heated by the flame, it will quickly melt and shrink by the surface tension, and the backside can be almost instantaneously heated by the flame. Therefore, we define the arrival of the fire front when the EPS back temperature had a sudden increase. As expected, the upward fire spread rate is not constant, but increases almost linearly with the time and the development of fire, as shown in Fig. 4(a). In other words, the acceleration of FSR in each is almost a fixed value. To simplify the comparison, the average value of FSR is used to study the influence of other fire and material parameters.

Fig. 4(b) shows that the averaged FSR decreases greatly as the thickness of EPS increases. Specifically, as the thickness increases from 100 to 200 mm, the thin material,’’ although the thicknesses of EPS are several orders of magnitude value of FSR almost decreases half. This behavior is the same as the ‘‘thermally-thin material,’’ although the thicknesses of EPS are several orders of magnitude greater than the conventional limit of thermally thin (about 2 mm). This is attributed to the quick shrinkage of EPS foam in contact with the flame, as well as the serious melt-flow or melt-drip phenomena [10] that happened inside the ETICS.

Fig. 4. The upward fire spread over EPS: (a) spread rate vs time, and (b) spread rate vs EPS thickness.

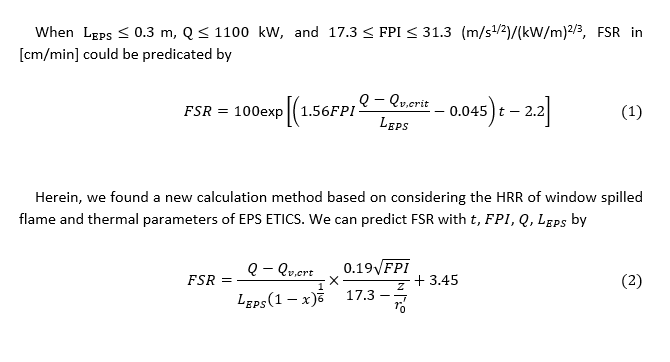

NEW METHOD TO PREDICT FIRE SPREAD RATE

In our previous work, a calculation method for FSR on the basis of test results from a series of tests is given [9].

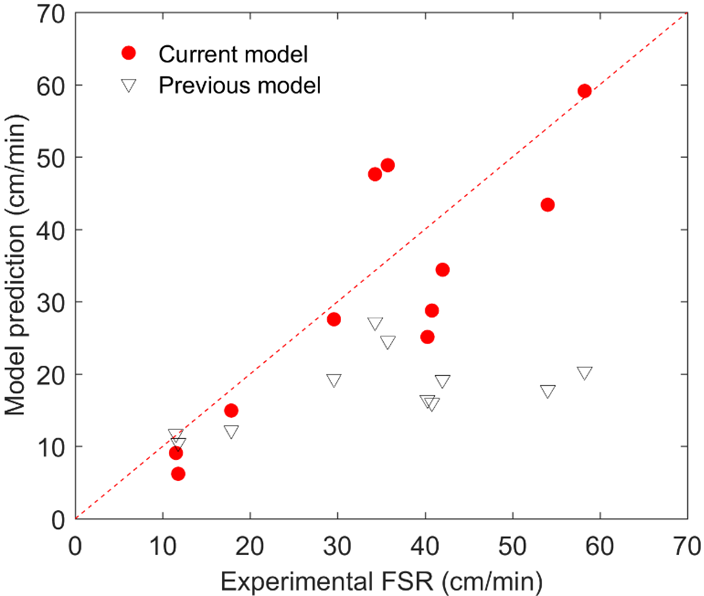

The comparison of experimental and calculated data is shown in Fig. 5. It indicates the result performed by the current method shows a better agreement with experimental data. Thus, the current method is adequately approximated for engineering applications.

Fig. 5. The deviation between experimental and calculated FSR by using two methods.

REFERENCES

[1] Potton E. Grenfell Tower Fire: Background. Number CBP 8305, House of Commons Library 2018.

[2] Zhou B, Yoshioka H, Noguchi T, Wang K, Huang X. Upward Fire Spread Rate Over Real-Scale EPS ETICS Façades. Fire Technology 2021. doi:10.1007/s10694-021-01103-3.

[3] Barreira E, de Freitas VP. Experimental study of the hygrothermal behaviour of External Thermal Insulation Composite Systems (ETICS). Building and Environment 2013;63:31–9. doi:10.1016/j.buildenv.2013.02.001.

[4] Nilica R, Harmuth H. Mechanical and fracture mechanical characterization of building materials used for external thermal insulation composite systems. Cement and Concrete Research 2005;35:1641–5. doi:10.1016/j.cemconres.2005.04.001.

[5] Hajduković M, Knez N, Knez F, Kolšek J. Fire Performance of External Thermal Insulation Composite System (ETICS) Facades with Expanded Polystyrene (EPS) Insulation and Thin Rendering. Fire Technology 2017;53:173–209. doi:10.1007/s10694-016-0622-2.

[6] Japanese Standards Association. Test method for fire propagation over building facades. JIS A 1310 Standard Test 2015.

[7] Zhou B, Yoshioka H, Noguchi T, Ando T. Numerical prediction of mass loss rate of expanded polystyrene (EPS) used for external thermal insulation composite systems (ETICS) in cone calorimeter. Fire and Materials 2018;42:517–26. doi:10.1002/fam.2495.

[8] Zhou B, Yoshioka H, Noguchi T, Wang K. Experimental study on vertical temperature profile of EPS external thermal insulation composite systems masonery façade fire according to JIS A 1310 method. Fire and Materials 2020:1–15. doi:10.1002/fam.2880.

[9] Zhou B, Yoshioka H, Noguchi T, Wang K. Experimental study of time-averaged upward fire propagation speed of expanded polystyrene external thermal insulation composite systems masonery façade. Fire and Materials 2021;45:193–204. doi:10.1002/fam.2923.

[10] Xie Q, Tu R, Wang N, Ma X, Jiang X. Experimental study on flowing burning behaviors of a pool fire with dripping of melted thermoplastics. Journal of Hazardous Materials 2014;267:48–54. doi:10.1016/j.jhazmat.2013.12.033.