Smoke Control Systems: A Guide to the Basics

By: Yasser Ahmed, PMSFPE

View full PDF here

Simplifying the Basics of Smoke Control

Do you find it challenging to understand how smoke control systems integrate with fire alarm systems?

Many people find it complex to comprehend how smoke control systems interact with fire alarm systems. If you are among them, you are not alone. Let's simplify the concept to make it easier to grasp.

Smoke control is a crucial aspect of fire safety engineering. It is designed to minimize the spread of smoke and toxic gases in buildings during fire incidents. These systems operate using various techniques, including mechanical ventilation, pressure differentials, and compartmentation, to manage smoke movement, thus ensuring the safety of both occupants and property. This guide provides an overview of the principles, design aspects, and applications of smoke control systems. Additionally, it highlights the regulations and standards governing their implementation. Whether you are a fire protection specialist, property owner, system installer, or simply interested in the topic, this article offers valuable insights into smoke control methodologies.

Integration of Fire Alarm Systems with Smoke Control

Fire alarm systems play an essential role in the activation and operation of smoke control mechanisms. These systems identify the presence of smoke and fire, alert individuals, and emergency responders, and trigger necessary smoke management actions. Additionally, fire alarms continuously monitor smoke control system performance, relaying crucial status updates to building management systems. For these systems to work effectively, they must be properly listed, compatible, and integrated to provide a coordinated response during fire emergencies.

Designing and Maintaining Smoke Control Systems

Smoke control systems are highly complex and require meticulous planning, installation, and maintenance. Their design should be based on a thorough analysis of fire hazards, building characteristics, occupant needs, and firefighting operations. This process involves creating a detailed report known as a "smoke control report" or "rational analysis," which must be completed by a registered fire protection engineer (FPE) under the International Building Code (IBC) 2021 Section 909.4.

The rational analysis outlines several key aspects:

- Selection between passive and mechanical smoke control systems.

- Identification of the most effective smoke management technique (pressurization, exhaust, or airflow).

- Construction methodology, sequence of operation, and testing protocols.

- Considerations for factors such as stack effect, fire-induced temperature variations, wind influence, climate conditions, and system operational duration.

- Integration with firefighting operations and evacuation strategies.

- Compliance with local, national, and international building and fire safety regulations.

Adopting this thorough approach ensures that smoke control strategies are tailored to the specific requirements of a building and its occupants.

Codes and Standards Governing Smoke Control

Smoke control systems are mandated and regulated by specific codes and standards that define performance requirements, design criteria, installation methods, and testing protocols for different types of buildings and occupancies. Some of the key documents include:

- 2021 International Building Code (IBC), Chapter 9: Fire Protection and Life Safety Systems.

- ASHRAE Handbook of Smoke Control Engineering.

- NFPA 92: Standard for Smoke Control Systems.

- NFPA 101: Life Safety Code.

- NFPA 72: National Fire Alarm and Signaling Code.

- Underwriters Laboratories (UL): Smoke Control Equipment (ANSI/864 units for fire protective signaling systems).

These codes and standards ensure that smoke control systems are designed, installed, and maintained to meet safety requirements and perform effectively during emergencies.

Where Are Smoke Control Systems Mandatory to Install?

According to the International Building Code IBC 2021, smoke control systems are required in the following scenarios:

- Atriums (three stories or more) within covered malls (Section 402.7.2).

- High-rise buildings (Section 403.4.7).

- Atriums (three connected stories or more) (Section 404.5).

- Underground buildings (Section 405.5).

- Enclosed parking garages with mechanical access (Section 406.6.4.2).

- Windowless buildings classified as Group I-3 (Section 408.9).

- Large stages (greater than 1,000 square feet in area or 50 feet in height) (Section 410.2.7).

These requirements are designed to address the unique challenges posed by these building types and ensure the safety of occupants during fire emergencies.

Regular Types of Smoke Control Systems

Smoke control systems can be broadly classified into two main categories: passive type systems and mechanical type systems.

Passive Smoke Control Systems:

These systems rely on natural forces like buoyancy and pressure differences to create ventilation openings that allow smoke to escape and fresh air to enter. Examples include automatic opening vents (AOVs), atrium exhausts, opposed airflow systems, and smoke reservoirs. Passive systems often incorporate devices such as fire dampers, combination fire-smoke dampers, and fire-rated doors with magnetic hold-open mechanisms. Activation depends on the approved rational analysis or smoke control report and may involve smoke detectors, heat detectors, or duct smoke detectors. Positive status verification is not mandatory under the International Building Code IBC 2021 Section 909.12.1 unless specified in the rational analysis. Wiring must comply with the National Fire Alarm and Signaling Code NFPA 70 and be enclosed in continuous raceways.

Mechanical Smoke Control Systems:

These systems use fans, dampers, ducts, and other equipment to manipulate pressure and airflow patterns to control smoke movement. Common methods include:

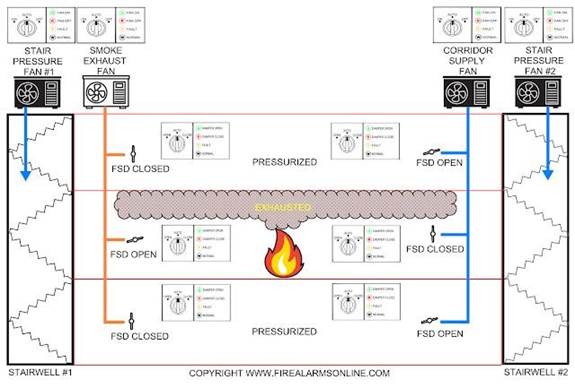

- Pressurization Method (IBC 2021 Section 909.6):

- This approach generates pressure differentials across smoke barriers to contain smoke movement.

- Minimum pressure requirement: 0.05" water gauge (IBC 2021 Section 909.6.1).

- Maximum door opening force: 30 lbs to initiate motion, 15 lbs for full opening (IBC 2021 Section 1010.1.3 #2).

- Full automation is mandatory, and electrical wiring must comply with NFPA 70 regulations.

Smoke Control Pressurization Method Detail

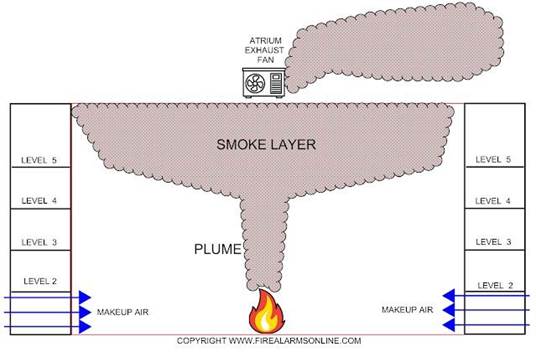

- Exhaust Method (IBC 2021 Section 909.8):

- Uses large exhaust fans to remove smoke from designated areas (e.g., atriums, malls).

- Replacement air may be supplied via mechanical systems, automatic windows, or doors.

- Smoke levels must remain at least six feet above evacuation pathways.

- Designed per NFPA 92, requiring full automation and NFPA 70-compliant wiring.

Smoke Control Exhaust Method Detail

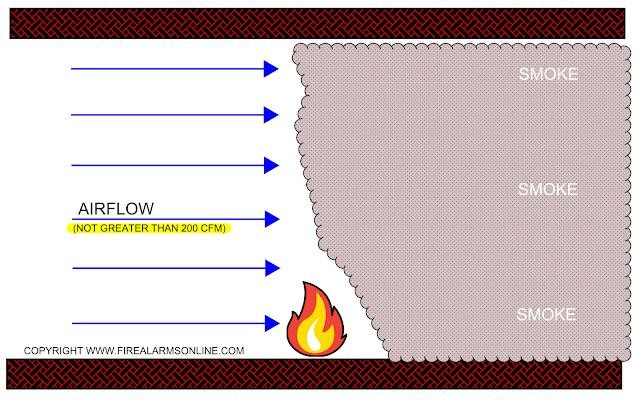

- Airflow Method (IBC 2021 Section 909.7):

- Utilizes airflow direction to control smoke migration.

- Air velocity must not exceed 200 feet per minute.

- System design must not negatively impact other smoke control measures, intensify the fire, or obstruct egress routes.

- Full automation and NFPA 70-compliant wiring are necessary.

Smoke Control Air Flow Detail

The necessary time for the smoke control operation

According to IBC 2021 Section 909.4.6, all active components of smoke control systems must function for a minimum of 20 minutes or 1.5 times the calculated evacuation time, whichever is longer. This requirement ensures that the system remains operational long enough to support safe evacuation and firefighting efforts.

The Role of Emerging Technologies in Smoke Control

- Hybrid Smoke Control Systems: Combining passive and mechanical approaches to optimize smoke management in complex structures.

- Computational Fluid Dynamics (CFD) Modeling: Advanced simulation techniques to predict smoke movement and optimize system performance.

- Smart Control Systems: Integration of artificial intelligence and real-time monitoring for dynamic response to fire incidents.

- IoT Integration: Enhancing smoke control monitoring through cloud-based analytics and automation.

- Advanced Materials: Innovations in fire-resistant materials and coatings improving the efficiency of smoke barriers.

Verification and Positive Status

Smoke control equipment in mechanical systems must comply with IBC 2021 Section 909.12.1, which mandates “verification” or “positive status.” This involves using fire alarm monitoring modules to supervise the activation of fans, dampers, and doors during a smoke control event. Components such as variable frequency drives (VFDs), end switches, pressure differential switches, and current switches provide contact closure to trip the associated fire alarm monitoring module, proving that the fan, damper, or door has activated as intended per the approved rational analysis or smoke control report.

Exceptions:

If individual components tested during the preprogrammed weekly test interfere with normal building operations, they may be bypassed if approved by the Authority Having Jurisdiction (AHJ). However, the presence of power downstream of all disconnects must be verified weekly by a listed control unit, and all bypassed components must be tested according to International Fire Code IFC Section 909.20.6.

Conclusion

Smoke control systems are a vital component of fire safety, mitigating risks associated with smoke inhalation and fire spread. Understanding their principles, design, and regulatory requirements ensures their effective implementation. By following proper planning, installation, and maintenance procedures, these systems can significantly enhance occupant safety and property protection during fire emergencies. Continuous advancements in smoke control technology, including hybrid systems, AI integration, and IoT advancements, further improve fire safety measures, ensuring buildings remain well-prepared for fire-related emergencies. The future of smoke control is moving towards more intelligent, predictive, and adaptive systems, providing greater reliability and efficiency in safeguarding lives and property.